Planning For Modularization

Planning for modularization is the evaluation and determination of offsite construction in the front end planning phase to achieve specific strategic objectives and improve the project outcomes. The process includes developing a business case and execution strategy for large-scale transfer of stick-built construction effort from the job site to fabrication shops or yards.

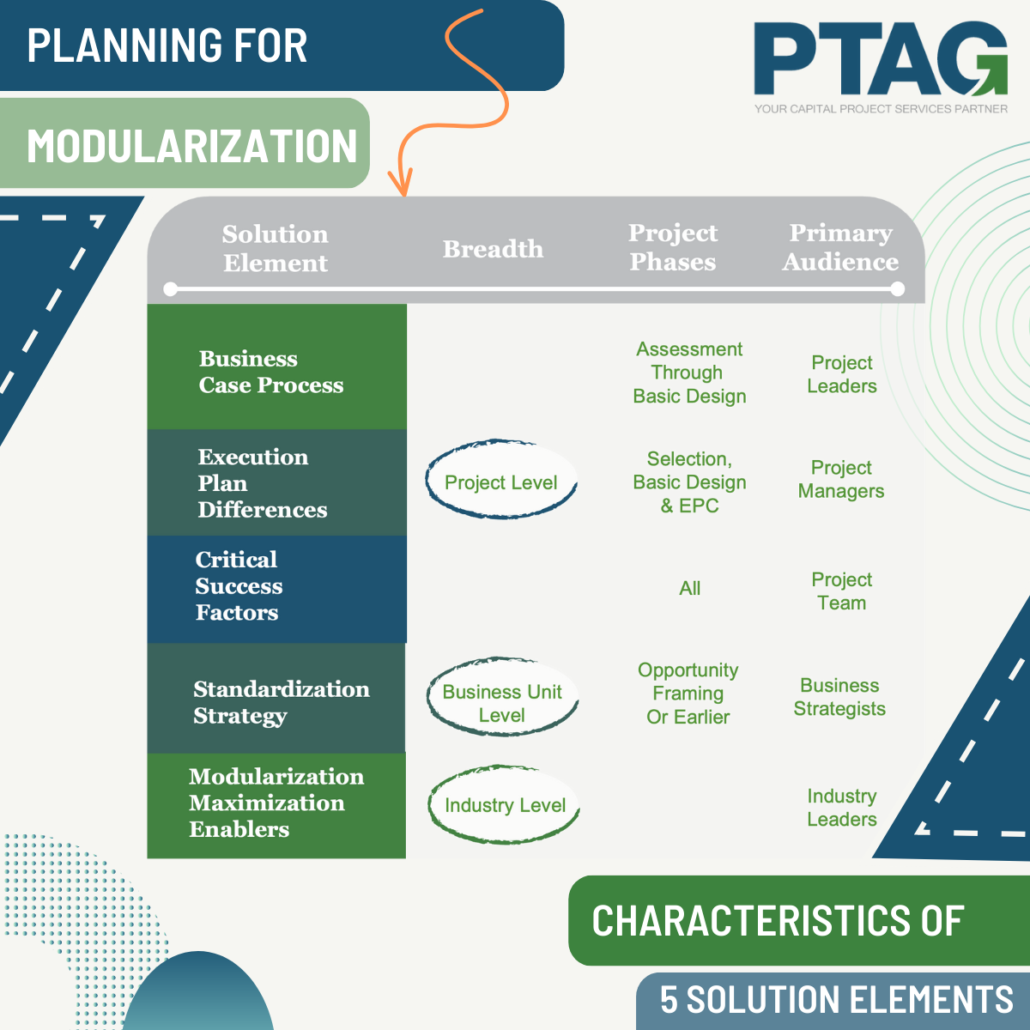

In order to achieve higher, more successful levels of modularization, industry and project

leaders should be attentive to the five different elements of the solution, as illustrated in the following picture:

- Business case process

- Execution plan differences

- Critical success factors

- Standardization strategy

- Modularization maximization enablers

The modularization business case process should be applied at the earliest opportunity. Project teams should consider the modular approach the “default” approach in order to

allow the advancement of modularization in the industry

Industry-wide barriers continue to challenge the broad-based achievement of high levels of modularization. There are ten maximization enablers to act as counter-measures to these challenges and to accelerate modularization across the industry.

At PTAG, our industry-specific teams are ready to implement modularization on your project to enhance various aspects of project management, including time, cost, safety, quality, and productivity.