Enhancing Project Delivery Through Structured Execution and Complexity Management

Effective project execution is critical to achieving business objectives, yet many organizations struggle with delays, cost overruns, and misaligned teams. The challenge lies not only in managing scope, schedules, and budgets but also in navigating complex stakeholder environments, regulatory requirements, and evolving market conditions.

PTAG’s Complexity Model and Project Handbook provides a structured, repeatable approach to project execution that enables organizations to improve efficiency, mitigate risks, and deliver consistent results. By applying proven methodologies tailored to the unique challenges of each project, organizations can enhance performance, optimize resources, and ensure alignment across all phases of project execution.

Understanding the Core Challenges in Project Execution

Many projects fail to meet their objectives due to a combination of internal and external challenges. PTAG has identified five key factors that commonly impact project success:

- Lack of Strategic Alignment: Misalignment between business objectives, project teams, and execution strategies leads to inefficiencies and costly delays.

- Ineffective Stakeholder Communication: Poor coordination across departments and unclear roles create disconnects that hinder decision-making and progress.

- Resource Planning Gaps: Shortages in skilled labor, supply chain disruptions, and inadequate contingency planning result in execution inefficiencies.

- Unrealistic Schedules and Budgets: Overly aggressive timelines and underestimated costs increase the likelihood of overruns and rework.

- Regulatory and Risk Management Challenges: Non-compliance, safety risks, and unforeseen project complexities can introduce significant financial and operational risks.

Addressing these challenges requires a structured approach that ensures clear governance, proactive risk mitigation, and cross-functional collaboration.

PTAG’s 10-Step Approach to Optimized Project Delivery

PTAG’s structured execution model is built around 10 key steps designed to streamline project management, improve decision-making, and enhance predictability.

1️⃣ Assess Market and Business Cycles – Evaluate external factors that may influence project viability and execution.

2️⃣ Define Success Criteria – Establish clear, measurable KPIs to align all stakeholders.

3️⃣ Evaluate Project Complexity – Categorize projects based on their complexity to apply the appropriate level of governance.

4️⃣ Develop a Detailed Execution Plan – Define key activities across engineering, procurement, and construction to ensure alignment.

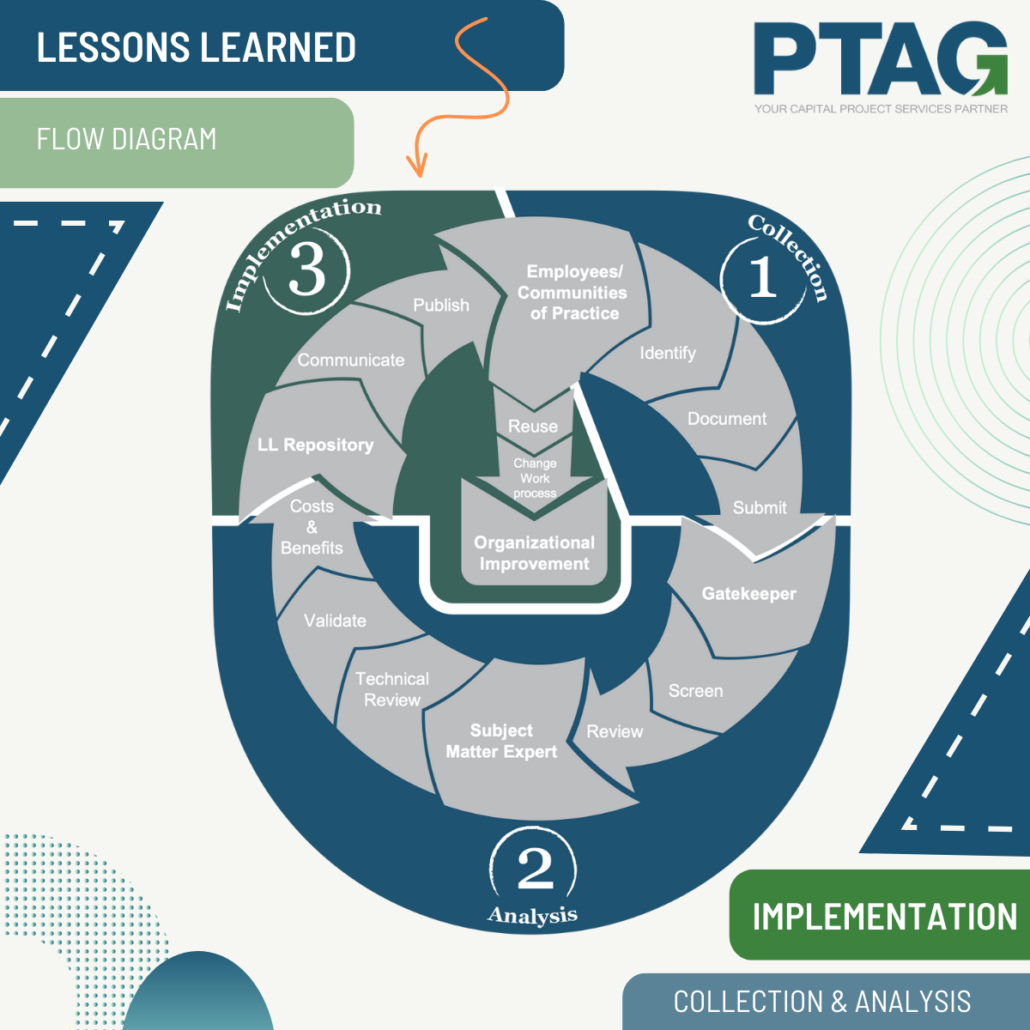

5️⃣ Leverage Best Practices and Lessons Learned – Apply insights from past projects to drive efficiency and risk reduction.

6️⃣ Optimize Value Engineering – Identify cost-effective alternatives without compromising quality or performance.

7️⃣ Strengthen Risk Management – Implement a proactive risk management framework to mitigate potential disruptions.

8️⃣ Ensure Integrated Project Management – Foster collaboration between engineering, procurement, and construction teams.

9️⃣ Enhance Stakeholder Communication – Establish structured communication channels to improve transparency and decision-making.

🔟 Align the Project Team – Ensure all team members are working toward shared objectives with clearly defined roles and responsibilities.

This methodology enables organizations to take a structured, data-driven approach to project execution, reducing uncertainty and improving overall performance.

PTAG’s Complexity Model and Project Handbook: A Tailored Approach to Execution

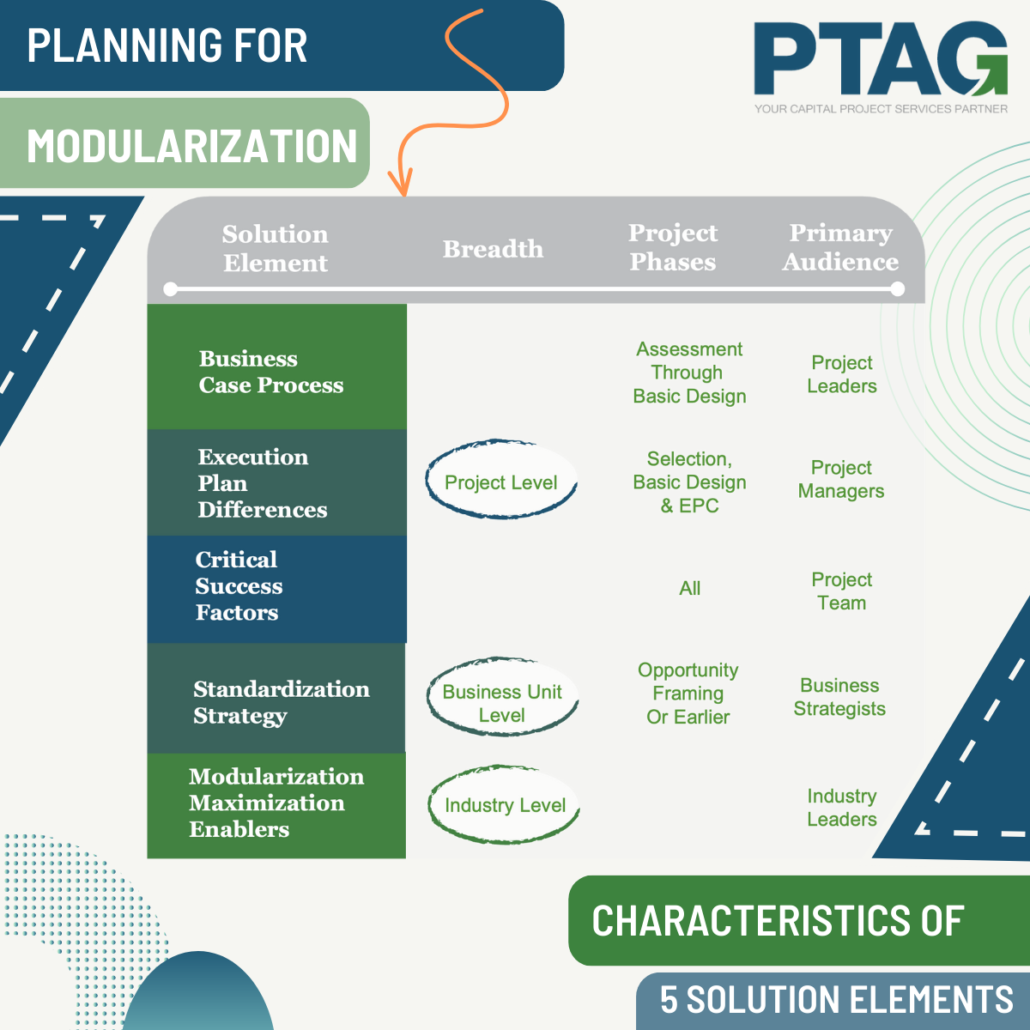

One of the most common challenges in project management is applying a one-size-fits-all approach to projects with vastly different levels of complexity. PTAG’s Complexity Model and Project Handbook solves this issue by:

✅ Classifying projects by complexity levels (C1 to C4) to ensure appropriate governance and oversight.

✅ Providing tailored execution strategies that match project complexity and risk profile.

✅ Integrating with project management systems for seamless implementation and adoption.

The Project Handbook is a practical, 60-70 page guide that provides a streamlined framework for execution, linking directly to best practices, tools, and methodologies. It eliminates ambiguity, ensures alignment across project teams, and drives standardization in execution.

Proven Impact: Driving Efficiency and Reducing Costs

Organizations that implement PTAG’s Complexity Model and Project Handbook experience measurable improvements in project performance:

📉 5-15% reduction in project costs through optimized resource allocation and risk management.

⏳ 3-10% acceleration in project schedules by improving coordination and execution efficiency.

📈 Stronger team alignment and stakeholder engagement through structured communication and governance.

🚀 Increased predictability in project outcomes by applying a standardized, repeatable execution approach.

By eliminating inefficiencies, reducing uncertainty, and improving decision-making, organizations can significantly enhance project success rates.

Achieve Greater Project Success with PTAG

Effective project execution requires a disciplined approach, clear governance, and alignment across teams. PTAG’s Complexity Model and Project Handbook provide a structured, proven framework for navigating the complexities of project delivery while optimizing performance and reducing risks.

If your organization is looking to improve project outcomes, reduce costs, and accelerate execution timelines, PTAG can help. Contact us today to explore how our structured execution approach can be tailored to your organization’s needs.