Overview

Company – Iron Ore Client

Industry – Mining – and Pellet Preparation

Category – Shutdown Planning and Construction

Project Budget – $35 million

Goal – Improved Detailed Planning, Shutdown Preparation, Outage Management, and Construction Productivity while meeting all safety requirements.

Obstacles – Brown field site, Old plant, Machine Rebuild in a tight fifty-seven-day shutdown (with 3 rounds the clock shifts) with Commissioning going on simultaneously while constructions continues.

Solutions – Subject Matter Expert assigned, assessed, and developed a compliant PCO processes, procedures, and supporting software. Additional staff assigned for implementation, administration, and transition for long-term support.

Results – Project Completed on time and budget vs 30% cost over-run and 2 weeks of delay costing the company significant lost production. Safety was good with no lost time.

Goals

To complete the Machine Rebuild within budget and time with no safety incidents

- Carry out the Outage for Machine Rebuild in a safe environment and to ensure start-up and operation after 57 days of shutdown.

- Improve site communication on a shift by shift basis

- Improve timely decision making

- Ensure Materials and Spares availability to avoid schedule slippage risk.

- Improve contractor performance

- Implement Lessons Learned procedures to ensure continuous improvement on future Outages

Obstacles

Management of Change and Implementation of Best Practices and Lessons Learned to Achieve the goals of the project

- Tight brown field site, with complex work processes

- Lots of vertical construction, pre-com, and commissioning starting within a week of shutdown. All while the machine rebuild, and other modifications were under construction

- Revised processes and procedures required to mitigate risk and achieve safety compliance that would require a culture change across the site

- Over 200 workers at site in tight conditions working three shifts 24/7

- Historic Project Execution planning practices

Solution

Developed and Implemented streamed lined processes for Project Controls and Contracts Admin Program to minimize and correct for Outage delays on a shift by shift basis to eliminate Outage schedule delays and cost overruns

PTAG’s Advisory Team was engaged in May 2017 to provide a complete assessment of past Outage programs to determine gaps and the develop improvements to achieve more reliable and certain cost and schedule outcomes. The team developed an improved execution plan with real-time project controls to execute the project on budget and time with no lost time accidents.

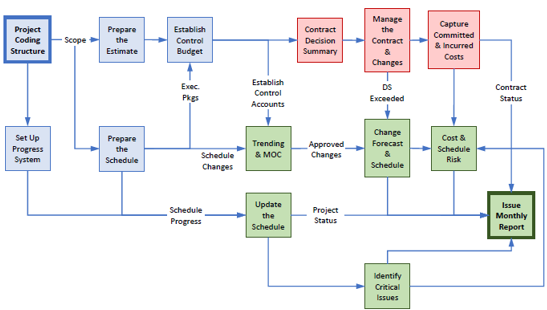

The Team developed and implemented the PCO processes and procedure (see slide 6) and developed a detailed list of deliverables and milestones to monitor and track the progress and state of preparedness of the Project before the shutdown.

There were 3 critical areas (1) list of items that needed to be addressed as shown in slide # 3 under “ Goals” (2) overall work flow processes were developed including RACI charts to ensure that everyone was aligned (3) implement a Field Management system so that daily progress data could be compiled, reviewed and analyzed on real time basis, allowing for corrective and timely actions to be taken on a shift-by-shift basis as opposed to typical weekly project reviews.

Improved timely decision making using detailed Organization RACI charts communicating who is responsible for change management and scope management, amongst other project functions.

Improved site communication and overcame the requirement for full face masks and a work environment with high-ambient noise levels by providing 2 positive pressure shacks located on each floor where masks could be removed, and where issues could be easily and openly discussed

To improve Contractor performance and acceptance of new control processes and feed back loops – A “Great Save” program that identified weekly the “best safety behavior” was implemented with rewards to the contractor for the best save.

A real-time QA/QC application was implemented to ensure seamless transition from construction to pre-com to commissioning to operation on a system by system basis.

PTAG PROCESS

SMEs Delivered, Implemented, Administered and Monitored the Program

- Review, Assess and Plan

- Report Results on Near – Real basis

- Develop Field Management Admin Program and FM Training

- Implement and Administer

- Monitor and Report the Results

- Plan for Next Machine Rebuild

PROCESS RESULT

Project Controls (PCO) and Contract Admin(CA) team members Delivered and Implemented the Project based on the overall process as shown below:

PTAG TEAM of SMEs developed and implemented new streamlined Project Control and Contract Admin processes from May 2019 to completion of the Project Dec 2019 to improve contractor feedback, corrective action, decision making and scheduling. The Program was tailored to work within site constraints and training over 200 workers in a congested area at site.

RESULTS SUCCESS

- Completed the 8-month project with 57 days of shutdown within budget and time

- No Lost Time Accidents

- No cost-overruns and claims as compared to previous 2 similar machine projects which were delayed by 2-3 weeks and 30- 40% of cost over-runs

- Past lessons learned and best practices were identified and implemented by Joint Client/PTAG team

- Implemented real time progressing at each work face of the round-the-clock shift work allowing timely corrective actions to be take on a shift- by- shift basis to maintain schedule vs typical daily or weekly review meetings.

ACHIEVEMENTS

“At the end of every shift we knew where we stood … and we could take timely and necessary corrective steps?”

Client Project Manager and Construction Coordinators

PTAG provides leading firms in the Power, Oil & Gas, Petrochemical, Mining, and Capital Infrastructure markets with qualified People, efficient Business Processes, and Information Management Systems that ensure consistently successful delivery and efficient operation of major capital projects.