Original Equipment Manufacturer Quality Performance Improvement Program

Company – Original Equipment Manufacturer – OEM

Industry – Electrical Generation

Category – Equipment Supply and Installation

Project Budget – Multiple Projects

Goal – Recovery action plan to improve quality performance to re-assure Owner that the OEM can be trusted to provide a reliable and warranted product

Obstacles – Global company with manufacturing facilities in numerous countries supplying equipment

Solutions – Conducted an internal analysis of both historical and active projects and audited their Quality Program. Recommended and supported the implementation of accepted actions items to address gaps in their Quality and Training programs.

Results – Improved quality results to assure Owner that the company can be trusted to reliably deliver on its commitments and jointly develop an “owner specific” approach aimed at improving customer satisfaction.

Goals

Improve Quality and Restore Owners Confidence

- Implement corrective actions to remain equipment supplier of choice

- Continuously improve equipment design and reliability

- Implementation of modern design tools and methods into the Quality program and training to targeted OEM organizational staff

- Develop QA/QC metrics used at different phases of the project and application of a more rigorous in-house inspection program

- Implementation of a revised quality manual to better suit Owner projects, including inspection and test planning early in the project lifecycle

- Minimize financial loss attributed to rework and deficiencies

Obstacles

Management of Change to improve quality performance

Challenges to meeting the goals of the project:

- Differing international interpretations of testing standards

- Compliance with published standards

- OEM Commercial position impacts on technical requirements and discussions

- Fully understanding the root cause in determining the needed corrective actions prior to revisions of the Quality program and supporting documentation

- Demographics associated with the coordination of training on and off site globally and ongoing refresher programs

- Program needed long-term monitoring of Non-Conformances and reporting to ensure continual improvement

Solution

PTAG’s Team of Subject Matter Experts Delivered and Implemented the Program

Original Equipment Supplier (OEM) was constrained from participating in any proposal submissions due to performance related issues until it was demonstrated to the Owner that existing technical deficiencies were addressed, and Quality program was enhanced.

The team developed and implemented the processes and procedural changes required for Quality improvement to their existing QA/QC program and identified areas for improved training opportunities. QA/QC Best Practices were deployed throughout the organization.

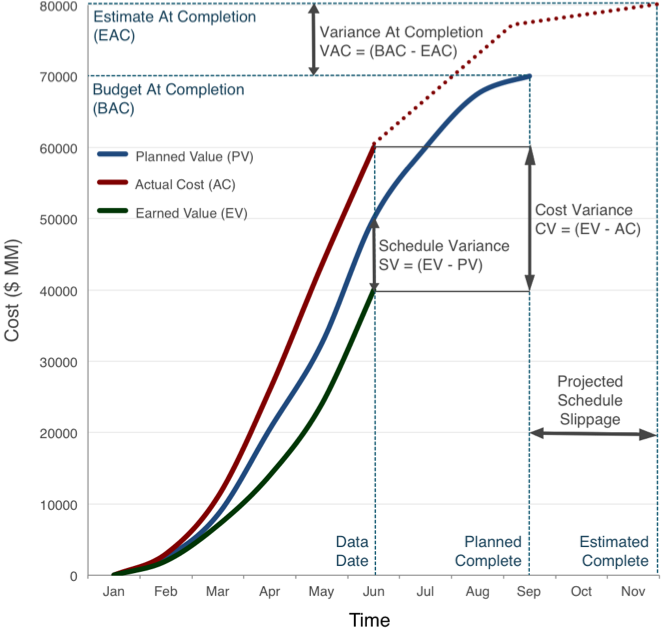

Mitigation plan was developed to limit the schedule impact of some of the on-going projects and to meet delivery requirements of future projects.

Identified the need for increased communication and provided a solution plan for a better communication structure to be applied at all levels of the OEM organization

Enhanced risk identification and control process were executed during the detail design, through manufacturing and installation phases

Constructed an internal audit process identifying findings and KPI measurements for improvement throughout all global facilities and on-site project locations. Team coached OEM project staff to identify and understand the planning techniques to mitigate the impacts of Non-Conformances

PTAG PROCESS

SMEs Delivered, Implemented, Administered and Monitored the Program

- Review and Assess

- Report Results

- Develop Program and Training

- Implement and Administer

- Monitor for Results

- Transition for Ongoing Support

PROCESS RESULT

SMEs Delivered and Implemented the Program

PTAG’s TEAM of 3 SMEs identified Quality Management Best Practices, delivered the expertise needed to modernize the organizations Quality Management program which resulted in a significant reductions in NCR’s and restored the CONFIDENCE of the Owner and its representatives

Owner was presented the OEMs action plan to enhance performance, improve quality, productivity, safety and eliminate rework occurrences

OEM welcomed suggested corrective actions from both the PTAG SME’s and Owner representatives to ensure the OEM remained the supplier of choice

Step 1: Define and Implement Your QMS

Step 2: Assess the Maturity of Your QMS

Step 3: Improve Your QMS

RESULTS SUCCESS

- OEM enhanced Owners satisfaction with a modernized Quality Management Program

- Business priorities are now linked in the Quality Management Program when developing and or supplying a piece of equipment

- Since the implementation of the revised Quality program, the organization’s culture continues to improve with the goal of zero Non-Conformance Reports

- Quality Program includes long range business planning objectives and ongoing performance assessments

- Quality program implements ongoing organizational learning, continuous improvement, sustainable work processes, productivity improvements, failure prevention, and conformance to requirements

ACHIEVEMENTS

- In house organization resources trained for assessing and improving the implementation of Quality Management Best Practices

- Performance metrics now embedded in the Quality Management Program

- Organization delivers products that meets Owners and Regulatory requirements

- Organization recognizes the importance of open and collaborative discussions in recognizing Owners requirements and expectations when interpreting technical specifications

- Significant reduction in projects that experienced over budget issues, late start-up, financial losses and unhappy board of directors and shareholders

- Recognized the need to define, identify and continuously improve in order to maintain Owners confidence

PTAG provides leading firms in the Power, Oil & Gas, Petrochemical, Mining, and Capital Infrastructure markets with qualified People, efficient Business Processes, and Information Management Systems that ensure consistently successful delivery and efficient operation of major capital projects.