Important Lessons learned from Modularization

Modularization entails the large-scale transfer of stick-build construction effort from the jobsite to one or more local or distant fabrication shops/yards to exploit one or more strategic advantages. However, the construction industry has been slow to achieve high levels of modularization. It has reached a ceiling regarding the percentage of stick-built work hours being exported offsite. The research effort led to the development of five distinct solution elements:

- Business case process

- Execution plan differences

- Critical success factors

- Standardization strategy

- Modularization maximization enablers

PTAG has industry-specific teams ready to address the question of what changes or adaptations in traditional project work processes are required to create an optimal environment for broader and more effective use of modularization. For successful modularization to occur, substantial owner involvement must occur early. The scope of research limited this team’s work to the industrial sector; however, its research findings may apply equally well to the commercial and infrastructure project sectors.

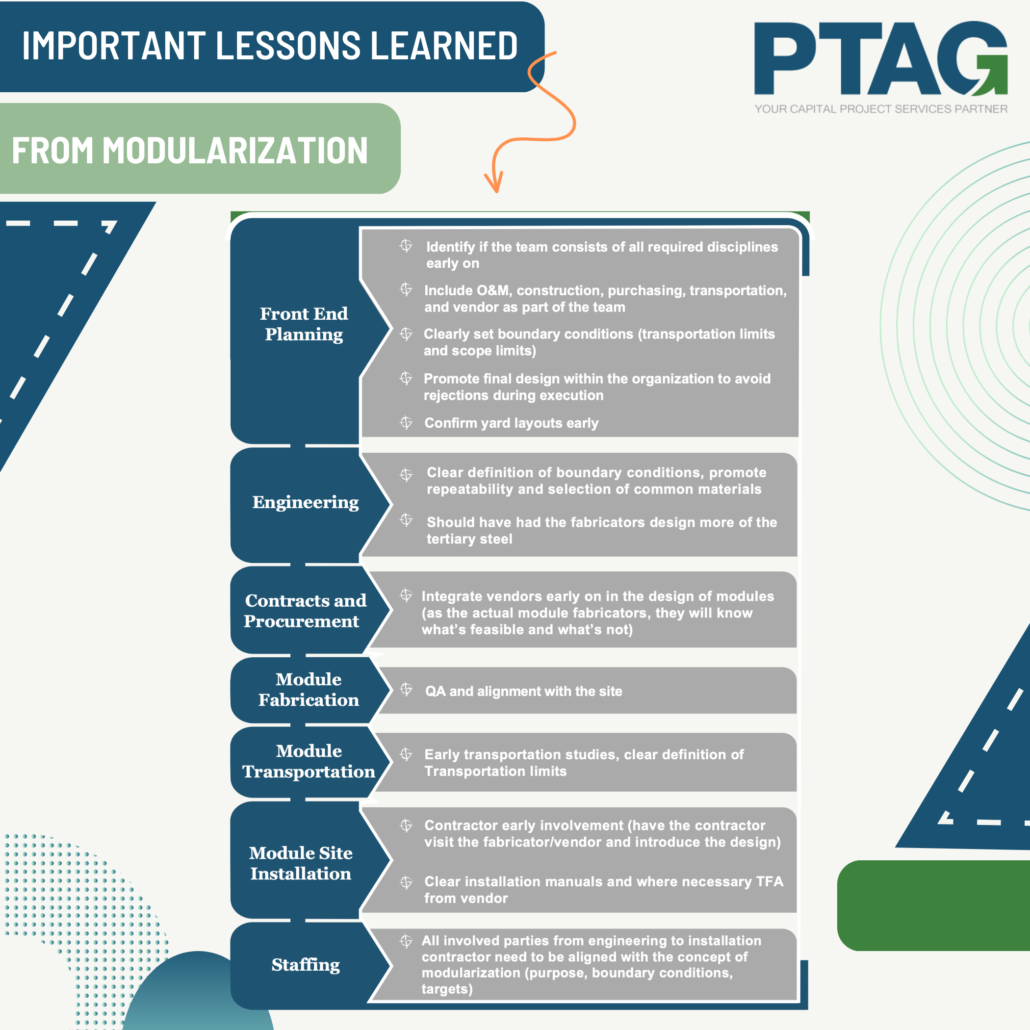

The following figure shows the lessons learned for Front End Planning, Engineering, Contracts and Procurement, Fabrication, Transportation, Site installation, and Staffing.