Throughout history, the construction industry has been identified as one of the most demanding and dangerous industries in the United States. Due to this both owners and contractors are investing more of their time and money to maintaining a good safety record. The importance of safety has become so important that the injury frequency rates that companies used to strive to achieve have now become unacceptable levels of safety performance for these companies.

What it is?

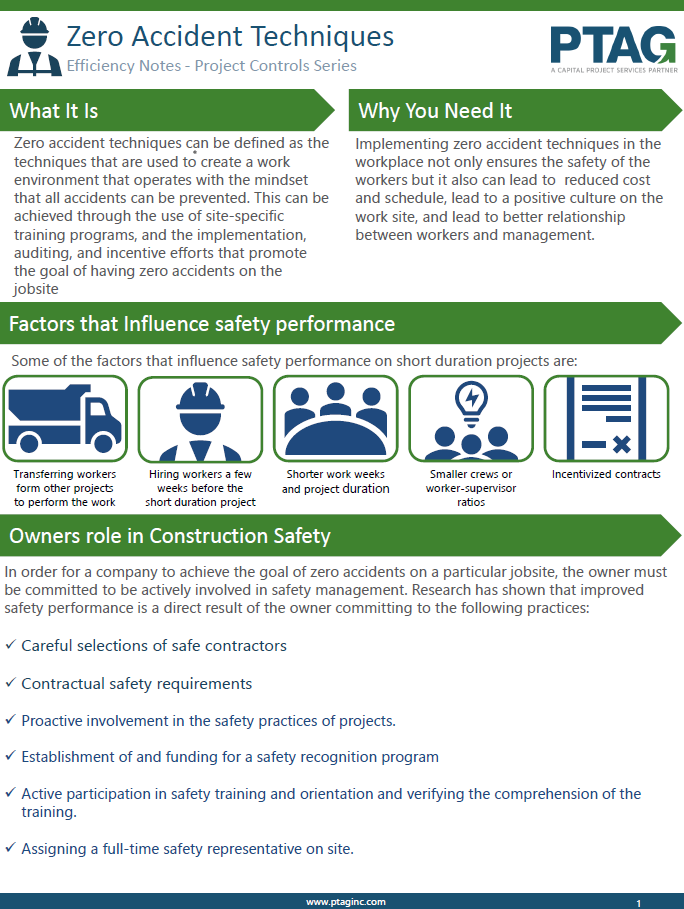

Zero Accident Techniques is defined as the techniques that are used to create a work environment that operates with the mindset that all accidents can be prevented. This can be achieved using site-specific training programs and the implementation, auditing, and incentive efforts that are enforced to promote the goal of having zero accidents on the jobsite.

Why you need it?

Implementing zero accident techniques in the workplace not only ensures the safety of the workers but it also can lead to reduced cost and schedule, lead to a positive culture on the work site, and lead to better relationship between workers and management.

Factors that influence safety performance

The information that was used to write this article was obtained from a research study that focused on short duration projects/shutdown projects. The findings obtained from this research study indicated that there are certain factors that can lead to a better safety performance on shutdown projects. These factors are:

- Transferring workers from other projects to perform the work

- Hiring workers a few weeks before the shutdown project

- Shorter work weeks and project duration

- Smaller crews or worker-supervisor ratios

- Incentivized contracts

Owners role in construction safety

It is the owner’s job to lead by example and set the tone for safety performance on a jobsite. The owner must be committed to actively demonstrate their involvement in safety management throughout all stages of the project. Research has shown that improved safety performance is a direct result of the owner committing to the following practices:

- Careful selection of contractors

- Contractual safety requirements

- Proactive involvement in the safety practices of projects

- Establishment of and funding for a safety recognition program.

- Active participation in safety training and orientation and verifying the comprehension of the training.

- Assigning a full-time safety representative on site.

Making Zero Accidents a Reality

The results of the study that were used to write this article reinforced the importance of several traditional safety methods and techniques employed by the construction industry and found effective new techniques. Through years of research on both construction safety and zero accident techniques, CII (Construction Industry Institute) has identified 10 key topic areas displayed bellow:

1. Management Commitment

- Upper level managers must demonstrate their commitment to the safety of their workers to promote project safety within the workplace. The importance of safety at the workplace is exemplified as management makes clear to the workers their dedication to safety. This can be accomplished using safety inspections, training and orientation, or accident and incident investigations.

- It is a frequent practice for firms to have a mission statement that is used to provide guidance for the direction of the firm. It is proven that greater safety performance will result from firms that incorporate safety in their mission statement.

- Research has shown that projects are conducted more safely when managers are involved in all aspects of incident investigation.

2. Staffing for safety

- Many of the large projects in operation will have full – time safety representatives on their job sites. Research has shown that greater attention was paid to safety issues when the safety representative was hired as an employee of the general contractor instead of a hired consultant.

- The safety representatives should be integrated within all project functions which means they should be involved in regular project management meetings and any shared reports relating to quality, costs, and scheduling with the safety personnel.

3. Pre-project and pre-task planning

- Pre-project and pre-task planning are when meetings are conducted that involve a job hazard analysis as well as contractibility reviews, both of which involve safety on the job site. To ensure that safety programs are relevant to the job site, site-specific safety programs should be implemented.

4. Safety education (orientation and specialization training)

- Training has been proven to be one of the most effective means for educating a worker about how to perform tasks safely.

- Studies have shown that companies that offer formal orientation training to all their employees have lower injury rates than those that do not.

- Studies also show that companies that provide additional specialized safety training to their workers experienced lower injury rates.

5. Worker Involvement

- Studies have shown that behavior-based safety programs as well as safety perception surveys are both effective tools that should be used to reinforce good safety practices and correct unsafe behavior.

- Behavior based safety programs use safety observers to help identify/correct unsafe behavior and reinforce good behavior. The observer can either be one of the general workers or it can be one of the supervisory personnel.

- Safety perception surveys are used to evaluate the overall status of safety on the jobsite by seeking information from workers.

6. Evaluation and recognition and reward

- Safety incentives should be used often to help encourage safety performance amongst the workers in a project.

- In general, companies that have better safety performances are those in which incentives are rewarded more often. This is due to the fact the greater frequency that incentives are awarded, the more often a company can show its commitment to safety.

7. Subcontractors Management

- A key component to any construction process is the use of subcontractors that will employ many of the workers on the site. It is essential for subcontractors to be included in the safety performance at the project level.

8. Accident/incident investigation

- Conducting accident investigations contributes to improving safety performance because it allows managers to learn from their earlier mistakes and prevents future recurrences.

- It is common practice for many companies to document near misses, which has been proven to be a significant influential factor in reducing accidents/incidents. A near miss can be defined as incidents that occur that can potentially cause bodily injury or property damage.

9. Drug and alcohol testing

- The consequences of substance abuse and the impact that it will have on safety performance are well known amongst companies which is why it is a widespread practice for large organizations to have substance abuse testing.

10. Contract type

- Research has shown that projects that are bound by a cost-plus contract have greater safety performance than projects that are bound by lump sum contacts.

- The reason for this is that the profits may be perceived as being compromised if more money is invested in safety for lump sum projects.